SCHNORR® fine blanking competency

SCHNORR GmbH is experienced in fine blanking technology e.g. the production of fineblanked disc springs and diverse precision parts. SCHNORR GmbH works in this area with different steel grades and also with difficult materials. The necessary heat treatment can be done in the SCHNORR factory.

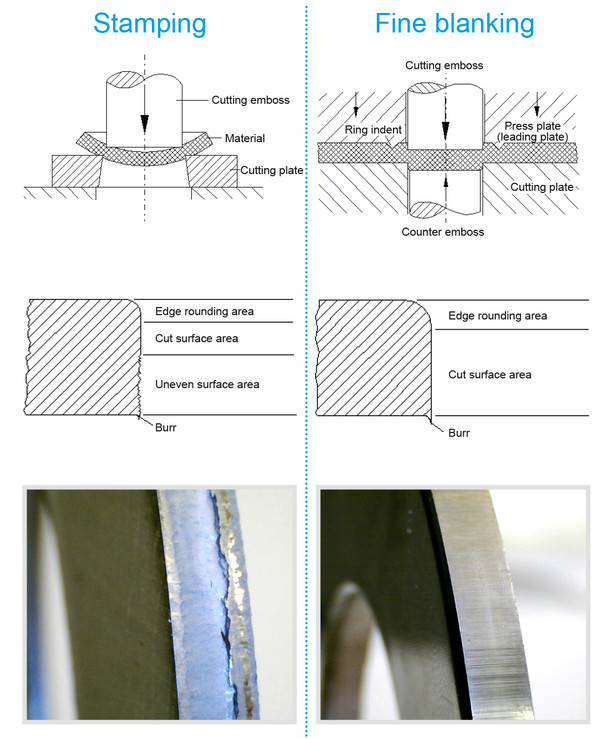

Fine blanking production Technology

Fine blanking is a type of production for a chipless splitting and, as required, forming of material. It enables the manufacture of high-precision components.

Advantages as against conventional stamping:

- much cleaner cutting surface.

- negligible need for reworking.

- very high angle precision.

- narrowly defined tolerances.

- more even surface.

- narrowly defined concentricity.

Technical production resources of Schnorr GmbH*

- several fine blanking pressworks.

- Cutting strength up to 2500 kN.

- max. band width 180 mm.

- max. material thickness 7 mm.

- standard materials: C75S, 51CrV4, X10CrNi18-8, X7CrNiAl17-7, DC04, C-Steels.

- production quantities starting from 1.000 pieces.

- multiple-falling tools possible.

* Feasibility concerning quantity, dimension and material properties needs to be examined for each individual case